Products

Chopped non-woven - Chopped fibres / Mixtures - Custom work - ground material

-

Chopped nonwoven for riding areas

GGT Additives for riding grounds – Quality that has been established for decades.

For more than 20 years, Polywert GmbH has been producing innovative products for the market of riding arena construction. This mainly includes our synthetic chopped nonwoven as well as different fibers (both with brand name GGT), which improve the equestrian footing as an additive that should be mixed with sand. Further a water storage granular material, made of volcanic rock dust and minerals (GGT Arpolith) and a professional riding mat are part of our production program.

We are your partner for expertise in this business and have a worldwide network of specialists for all disciplines in equestrian sport. Together with our partners, we ensure that the riding arenas, whether they are tournament arenas, hobby arenas, gallop racetracks, western or carriage ride surfaces, riding arenas of breeding and training stables or riding schools, are adapted to the requirements in order to achieve an optimal and customized result.

Not only professional riders put more and more emphasis on an optimal bottom layer. It is the guarantee for best training and tournament conditions as well as for keeping the horses healthy. Joint and tendon disorders due to false riding floors do not have to be. For our customers, we develop special mixtures, which are costumised for different sand qualities or equestrian requirements. Flexibility, quality and costumer service as wll as decades of experience are our strengths.

For our products you get test certificates and safety data sheets. Our own production in Germany ensures a high quality standard (DIN ISO 9001+).

- GGT Chopped non-woven

- GGT Fibers

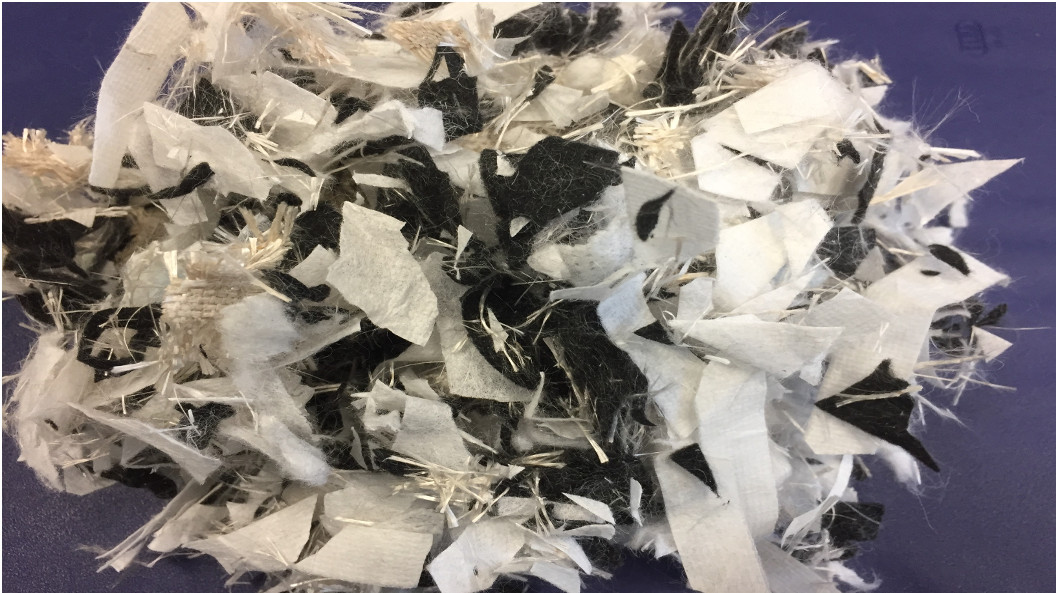

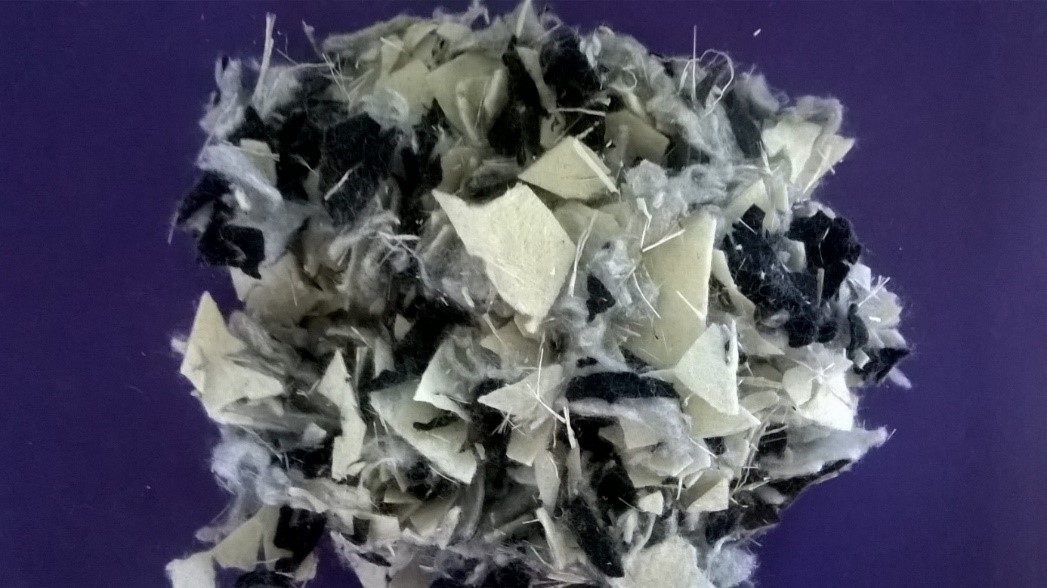

- GGT Special mixtures

- GGT Equilastic

- GGT Western

- Additives for riding ground

-

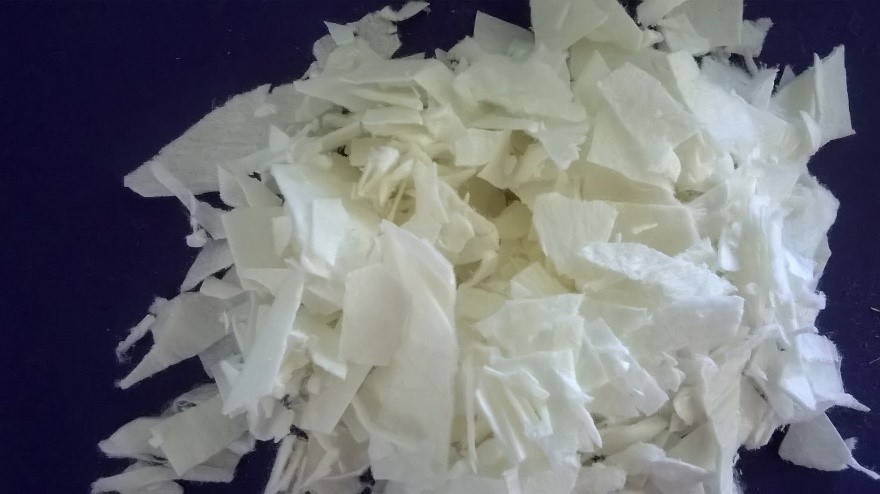

GGT Geo white

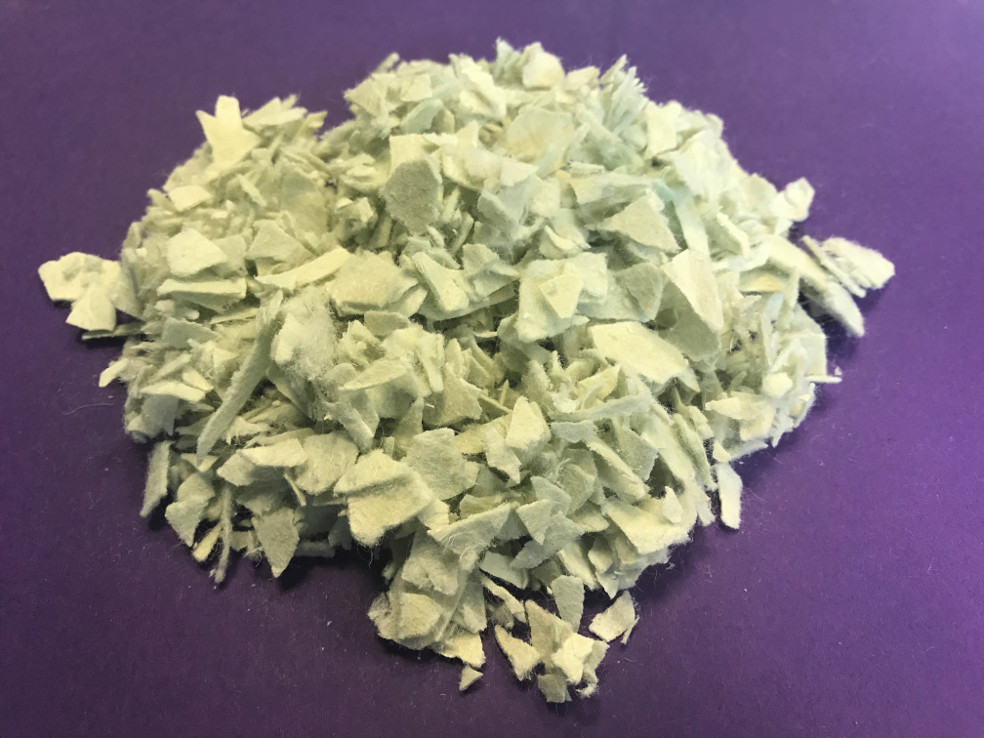

GGT Geo green

GGT Eco coloured

GGT Chopped non-woven:

With our GGT chopped nonwoven chopings as an additive you improve riding surfaces, round pers or race courses. Optimal accessibility, ease of care and moisture-regulating effect are just some of the advantages of these products.

By synthetic additives in riding sand, the ground of riding areas and riding halls are sustainably improved to create the best conditions for all riders. Also in the daily training of the horses one should pay attention to an optimal subsoil, which meets the requirements of rider and horse at all times.

Professional installation of the tread layer mixed with GGT Chopped non-woven, is the guarantee for a perfectly functioning riding ground for many years. For all our products it´s important to match them with the riding sand.

GGT Geo and GGT Eco: pure Chopped non-woven varieties -

GGT PES Fibers

GGT BIO Fibers

GGT elastic Fibers

GGT Fibers

Our fibers are pure or as an admixture in the non-woven fabrics. Fibers act like a root system in the sand soil and primarily improve the stability and shear strength of riding floors. Here we also have the possibility to produce a fiber in biocompatible quality. -

GGT Dressage white

GGT Jumping green

GGT Basic

GGT Eco Dressage

GGT Special mixtures:

Depending on the customer and requirements, a wide variety of materials can be mixed, so that easy and user-friendly mixing in the riding field is ensured. In the spring mixes, a higher proportion of fibers is added to improve the shear strength of the soil. This also improves stability in the case of pedal layers for gallop racetracks or tracks or riding surfaces for carriage riding. Customized mixtures are no problem for us.

-

GGT-Equilastic - Tune-up your Footing

GGT-Equilastic Pur

Equilastic is an additive for riding surfaces which is made from controlled new goods (EPDM) and is used for riding surfaces (outdoor as well as indoor arenas). More elasticity in the footing sustainably improves the rideability and protects the horses’ joints in the long run. In addition with the suitable sand, the product may help the surface to get looser at simultaneous shear strength.

The product prevents soil compaction and may also in case of strongly compacted surfaces upgrade the footing by getting more elastic again.

GGT-Equilastic Mix

Our GGT-Equilastic Mix is a combination with our GGT Geo chopped nonwoven. That way, you get a blend that is highly versatile in riding surfaces which thus will be improved.

Pre-mixing the materials in our plant optimally combines the advantages of both products in a user-friendly way. The GGT chopped nonwovens improve shearstrength as well as moisture retention of the footing. They sustainably prevent compacting of the riding surfaces and have been proven for decades as additives for riding surfaces around the world.

By adding GGT Equilastic the surface will get slip-resistant and stable without getting too deep. Offering good spring and energy recovery in the riding sand this product is gentle to the horses’ joints.

-

The patented riding surface for Western riders: GGT Western

The Western sector is one of the major disciplines of equitation. More than 32,000 registered Quarter Horses and 5,700 breeders speak for themselves. Nowhere outside the American continent will you find more Western horses than in Germany.

But so far there have not been any professional solutions for the construction of riding arenas that were designed especially for the Western riders and work with textile additives. This is changing now with the GGT Western riding surface by Polywert GmbH in Bobingen.

We developed a footing for the Western riders’ special requirements which ideally accommodates your needs. Get to know the GGT-Western-System! It is worth doing it!

GGT Western

The first riding surface in the Western sector that meets the requirements of all Western disciplines

No matter if Reining, Cutting, Pleasure, Cow-Horse, Barrel-Race, Trail: This footing has been especially developed and tested for the Western equitation.

The footings that have been so far established and approved worldwide in dressage and jumping had been a no-no for the Western equitation. It has been claimed that the requirements in this equitation discipline would be too different. GGT-Western is changing this.

This new footing had been successfully tested by a professional for several months. Its special blend of different components makes this footing to what it is:

• shear-resistant and compact for the Cutting work with cattle

• sufficiently loose and smooth for Western dressage

• slidable for sliding stops

• easy to maintain and durable

• dust-free to take account of man’s and horse’s health

• hoof-friendly and moisture regulating

• the additives are tested for harmful substances and highly loadable

-

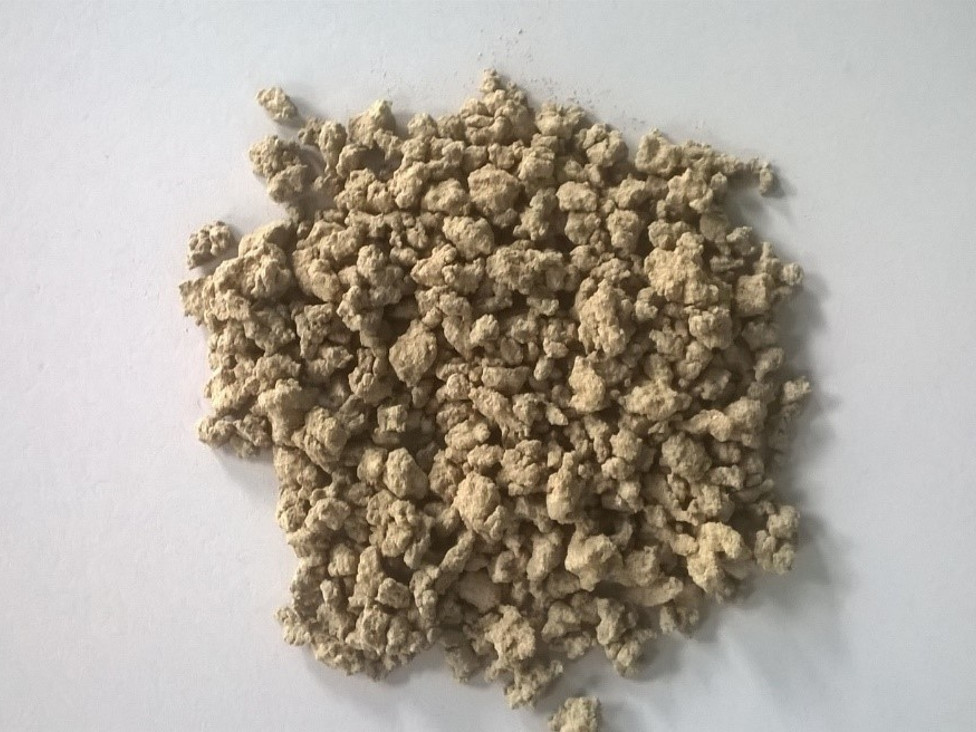

GGT Arpolith

The water storage granulate on a natural basis, which is a real problem solver for dusty or too dry riding grounds. Reduces puddling in the outdoor area and shortens your irrigation intervals. Also applicable in water protection areas. Maintains its effectiveness for 2 years in the soil.

GGT Butterfly Mats

Professional riding mat as the ideal separation between the base and the body. Our riding mat is available with or without drainage holes. Water storage cups in the mat as well as a structured surface offer safety and comfort. Easy installation by groove seam for optimal mat connection.

-

Ground material & Custom work

Our plants are able to crush different kinds of plastics (eg PE, PP, PVC, PE-LD) as well as to produce ground material for various fields of application.

We would be pleased to advise you on the possibilities and requirements for this production process of custom work by our team.We will send you a customized offer for contract work on our cutting mills for your products.

Business Hours

Monday - Thursday:

08:00 am - 5:00 pm

Friday:

08:00 am - 2:00 pm

Address

Polywert GmbH

Straßberger Straße 5

86399 Bobingen

Germany

Contact

FON +49 (82 34) 96 02 - 0

FAX +49 (82 34) 96 02 – 30

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.polywert.de